Manufacturing Software Development Services

Transforming with Modern Tech Solutions

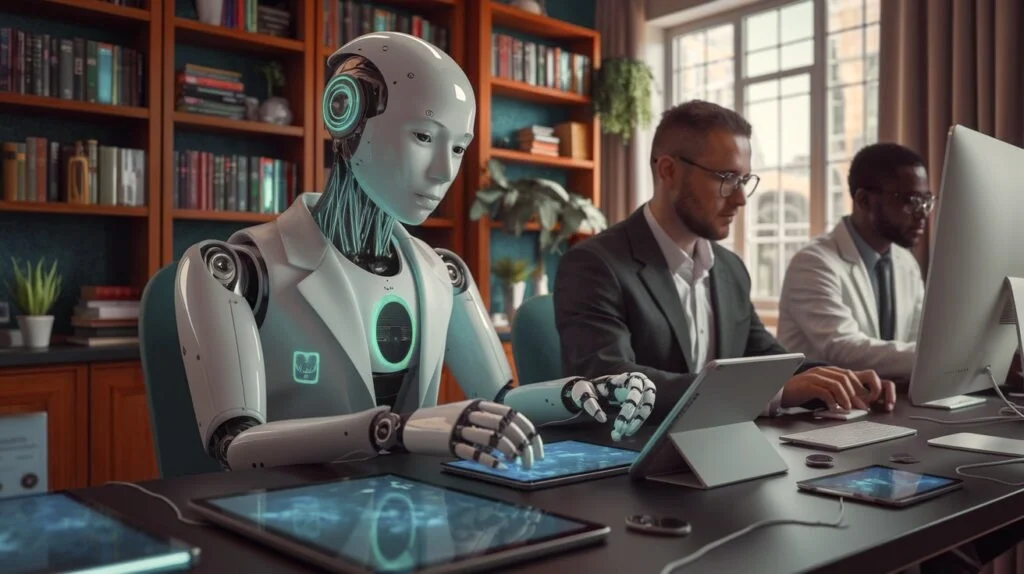

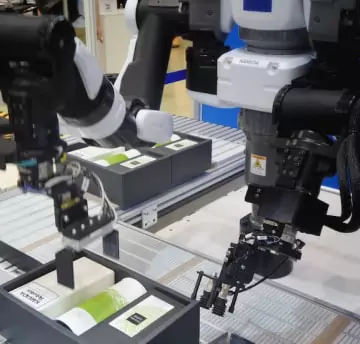

To remain competitive and increase efficiency, manufacturers must adopt modern solutions such as Industry 4.0, IoT, robotics, AI, additive manufacturing, AR, and digital twin technology, which optimize production processes and enhance customer satisfaction for greater productivity and sustainability in a dynamic marketplace.

Key Insights

Manufacturing Transformation over of 5 years

Industry 4.0 integrates digital technologies with manufacturing and is projected to reach in 2025 by.

AI optimizes production processes, and its manufacturing market is expected to reach in 2026 by.

AR transforms manufacturing by enabling workers to interact with virtual objects, with a 2020 market value of

Exploring the Importance of Technology in Modernizing Manufacturing Businesses.

Related IT and Software Solutions for Manufacturing

Enterprise Resource Planning (ERP) software

ERP software can help streamline operations by integrating various business processes such as accounting, inventory management, and supply chain management.

Product Lifecycle Management (PLM) software

PLM software can help manage the entire lifecycle of a product from design to production and beyond, ensuring that products are manufactured efficiently and to the highest quality standards.

Manufacturing Execution Systems (MES) software

MES software can help manufacturers track and monitor production processes in real-time, allowing them to identify and address inefficiencies or issues as they arise.

Supply Chain Management (SCM) software

SCM software can help manufacturers optimize their supply chain by improving visibility, reducing lead times, and optimizing inventory management.

Quality Management Systems (QMS) software

QMS software can help manufacturers ensure that products are manufactured to the highest quality standards by automating quality control processes and providing real-time monitoring and reporting.

Computer-Aided Design (CAD) software

software can help manufacturers design and develop products more efficiently and accurately, reducing lead times and improving product quality.

Internet of Things (IoT) software

IoT software can help manufacturers optimize their operations by connecting machines and devices to the internet, allowing for real-time monitoring and analysis of production processes.

Robotic Process Automation (RPA) software

RPA software can help automate repetitive and time-consuming tasks, freeing up employees to focus on more value-added activities.

Artificial Intelligence (AI) software

AI software can help manufacturers optimize production processes by analyzing data and providing insights into how to improve efficiency and quality.

Augmented Reality (AR) software

AR software can help manufacturers improve employee training and maintenance activities by providing immersive, interactive experiences that enhance learning and knowledge retention

Developing effective strategies for Manufacturing organizations: Key focus areas to consider.

All important features to learn anywhere, anytime online

Increased Efficiency

Software automates tasks, optimizes production, and increases efficiency while reducing waste.

Enhanced Visibility

ERP and SCM software improve decision-making and responsiveness by providing visibility into operations and supply chain.

Improved Product Quality

QMS and CAD software improve product quality, reduce defects, and increase customer satisfaction.

Better Data Management

MES and AI software can capture and analyze data, providing insights to improve operations and productivity.

Increase Cost Savings

Software solutions improve efficiency, reduce waste, optimize production, and increase profitability in the long term.

Increased Flexibility

Software solutions enable organizations to quickly respond to new challenges or opportunities in changing market conditions.

WHY CHOOSE US?

Let IndiaNIC handle your Manufacturing technology outsourcing needs

Cost-effectiveness

Cost-effective solutions without compromising quality or expertise.

Quality

Proven track record delivering high-quality work, meeting deadlines, and providing the best solutions to clients.

Flexibility

We adapt to clients' changing needs to ensure our solutions meet their requirements.

Communication

Responsive communication and work closely with clients to understand their needs.

Security

We prioritize data privacy and use strong security measures to protect client data.

Expertise

Tech experts mastering regulations and standards, offering specialized solutions for all your needs.

Take a closer look at our projects for the manufacturing industry

FAQs on IT Solutions for Manufacturing Industry

-

Life Technologies

-

Jackson Coker

-

McDonalds

-

Vodafone

-

Adidas

-

Oracle

-

MTN

-

MTU

-

BCG

-

Sancho BBDO

-

Smithfield

-

Best Buy

-

Essilor

-

Cosmopolitan

-

Abbott

-

UNSW

-

Daman

-

AstraZeneca

-

VFS Global

-

Haas

-

Tata

-

Yahoo

Schedule a Meeting with Our Experts

Share a brief about your project and get a guaranteed response within 24 hours.